The use of advanced technologies in the production of custom auto parts has benefited the sector in many ways. One of the most used technologies to save problems in auto parts development is rapid prototyping. Thanks to it, companies can avoid many design flaws and achieve considerable resource savings. Want to know more about custom car parts and accessories, you may go here.

It can be made for any quality you are looking for since the range of materials with which it can be worked varies: plastic, photopolymer, or metals. Also, it allows prototyping and short product runs.

Applications of Rapid Prototyping

With rapid prototyping, you can create objects similar to others. In this way, you can test them before launching them without spending resources. This type of prototyping is industrial and is used as the previous step to making a series of products. In addition, it allows us to have our prototype in a considerably short space of time.

There are many applications of prototyping, the production of custom auto parts being the popular one. Many techniques can be used for shorter series. We are going to see some rapid prototyping techniques that can help you produce not only the first prototypes but also the first runs of custom auto parts.

Techniques Used for Rapid Prototypes in Custom Auto Parts

There are several rapid prototyping techniques used in the creation of automotive prototypes. They include:

3D Printing

The most common way to create rapid prototypes is with three-dimensional printing. Within this group, four different prototyping processes can be used in the production of custom auto parts. They include:

Stereolithography and Selective Light

With this rapid prototyping technique, car parts can be created with photosensitive resin that is worked with UV light. If the light was not a beam, but a lamp, the technique would be Selective Light. The two methods are based on the same principle and achieve very similar results.

The base will be introduced in special resin, and as it covers the base, the beam of light hardens the resin in small layers until the piece is finished. When finished, the excess resin is removed and cured in a UV oven.

Selective Laser Sintering (SLS)

With selective laser sintering, creating a specific car part is also layered, but fusing the powder. The result is a very resistant piece, although it will depend on the type of powder. The fusing is done with a very powerful laser beam that melts them. The main advantage is that the powder bed acts as a support.

The most used material in this technique is nylon or polyamide powder, and the method is very suitable for manufacturing short series and 100% functional parts, as well as being one of the most economical. You can get the best custom auto parts from this technique.

Molten Material Deposition

It is another of the most popular techniques in 3D printing. The used material is wound on a spool-shaped like a fine filament. This filament melts in the printer and diffuses through a nozzle.

The most economical technique is this, and it works for any phase of production. Of course, the finish and resistance are the Achilles heel of this technique.

Polyjet (Triple Injection)

With this rapid prototyping, you can create objects combining materials and colors using photopolymers that are worked with ultraviolet light. This method does not work in layers.

In this case, the print heads pour micro droplets of material onto a platform. As this happens, UV light solidifies matter.

It has the advantage that the resulting automotive does not require post-processing. Of course, these pieces are not functional.

With Laser Cut

This is one of the most versatile techniques and is often overlooked. The cost is considerably lower, but of course, the material has to admit it. With laser cutting, many materials can be processed, and in metals, complex shapes can be made by being bent.

The main advantage is that the same design can be used to produce the parts. You can make many custom auto parts without having to modify them.

Design Flexibility

Design flexibility is one of the most important aspects of rapid prototyping. With a rapid prototype, you can quickly create a model of your Auto Part that you can then tweak to determine if it meets your specific needs. If you need an idea for your prototype, check here to get guidance on your project.

Since rapid prototyping is such an affordable and fast way to make changes, you can easily create multiple versions of your Auto Part to see which one works best. You can also use rapid prototyping to test different materials and finishes to find the perfect solution for your project.

Rapid prototyping also allows you to iterate on your design quickly, so you can make sure that it meets all of your requirements. With a quick turnaround time, you can explore different designs and solutions until you find the one that works best for your project.

Rapid Prototyping With CNC Machining

CNC is also often called machining. We could say that what this prototyping technique does is eliminate material from the initially used block of material with which the part will be made. This way, the shape we are looking for is obtained, and generally, the material used is metal.

Although it is a prototyping form, it is not as effective in terms of agility or as versatile as the ones we mentioned above. It still stands out as one of the most effective ways to produce custom auto parts.

Types of Rapid Prototyping Options Available for the Production of Car Parts

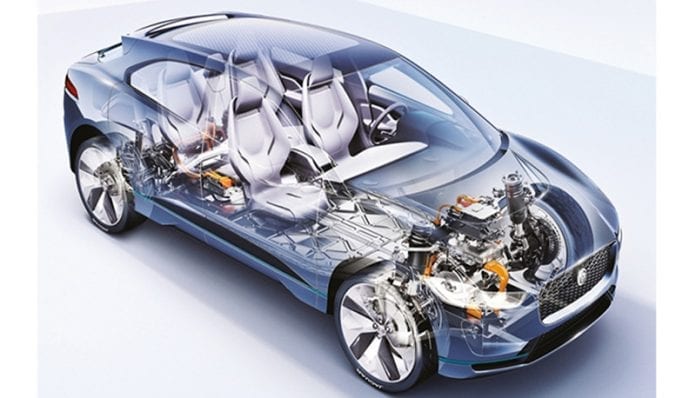

These types of prototyping that we are going to talk about are not functional; they have a purely aesthetic value. This is one thing most car companies look for to develop some of the most appealing designs. Here are some of the options available.

Of Design

These prototypes are used to physically see what the final appearance of the product will be. This will imply that user tests will be necessary to see if the product’s usability is good or not. In this type of prototype, post-production is essential to provide the look we are looking for.

Of Geometry

They are used to view volumes and spaces. When you want to check if an object fits inside another, this is the type of prototype you need.

Functional

The functional tries to analyze and see the ergonomics, since it depends on whether it can be put to good use. It is suitable for creating different mechanisms and knowing for sure if they respond to the needs in terms of fitting with other car parts or their movement.

If we want to see what functions the part will have, you need the technical prototype. With it, the definitive tests of the product are carried out.

The Importance of Rapid Prototyping for Car Parts

As we have said, when you develop a product, you can spend a lot of money if you do not create it properly. Prototyping helps us determine the suitability of each of these final prototypes, avoiding many errors that can cost us many resources. This makes it one of the best options for the production of custom auto parts.