With so many different plastics in the market, and so many plastic prototype manufacturers springing up, choosing the right option can be a daunting task. Here are some facts that were given by WayKenRM.com, which can maybe give you better answers.

Introduction

Plastics play a major role in everyone’s life. With more and more people are looking for things that are durable, cheap, and well processed, plastics are now an integral part of society. Just look around you, and you will find many daily use items made with some different types of plastics.

Though the world has progressed and has given us many different types of plastics, being a manufacturer, choosing the right one for your product can be a daunting task. Even harder is the selection of the right prototype manufacturer.

So let’s discuss some of the widely used plastics, their pros, and cons along with their uses. Once you have finalized the right for your product, then look into how to choose the right plastic parts manufacturer.

This blog is, therefore, divided into two main parts. The first section will give you information about some of the preferred plastics in the market today, followed by how China is dominating the plastic prototyping industry and why it is important to choose the right prototype maker for your product.

Nylon

Though Nylon is not brittle and rigid like other plastics, it is really strong and flexible. Nylon is the material of choice for many clothes and backpacks that need to be strong and requires waterproofing.

Advantages of Nylon

- Flexible and strong at the same time

- Great resistance to wear

- Do not shatter

- Good heat resistance

- Lightweight and durable

Disadvantages of Nylon

- Prone to reaction with chemicals

- Corrosive

- Underperform in Sunlight

- High Shrinkage rate – not suitable for injection molding

- Swells underwater

Common uses of Nylon

Nylon is used in everyday application as a durable fiber that requires longevity and strength. Nylon can be seen in bags, and clothes and accessories made with them are usually strong and used in outdoor activity-related products. Nylon is also used in the manufacturing of tires since they give the strength of the tire rubber and results in fewer tires puncture.

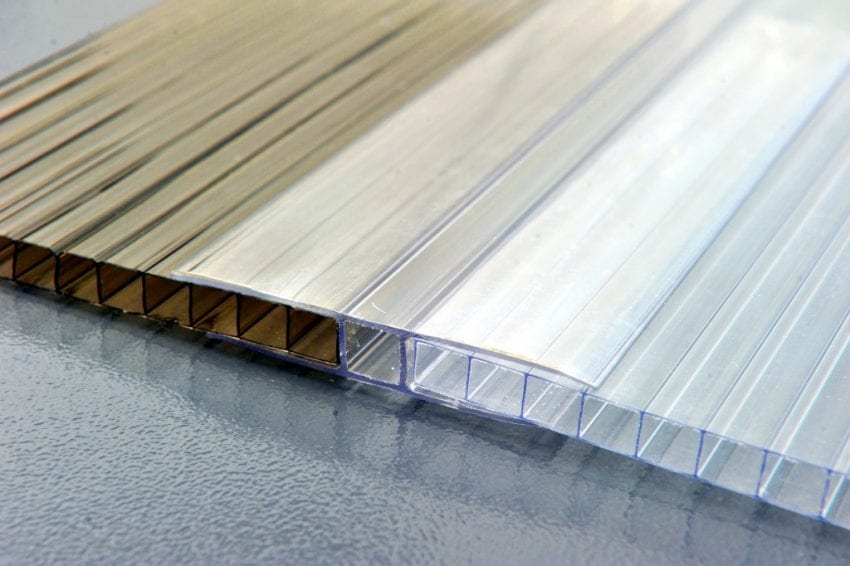

Polycarbonate (PC)

PC is used as a stronger and more durable alternative to glass. PC is transparent and can also be tinted according to the desired color.

Advantages of Polycarbonate

- Higher shock resistance than standard glass

- High heat resistance and can work at temperatures higher than 150°C

Disadvantages of Polycarbonate

- Tend to lose its transparency over time due to UV light

- Low resistance to scratches

- It can emit harmful vapors over time.

- Not suitable for food coverings

Common uses of Polycarbonate

PC is commonly used in locations where the use of glass is either expensive or not durable to use. PC can be seen as ineffective use in a traffic light, headlights and backlights of cars as well as reinforced glass in some locations. PC is also a cheaper alternative to PMMA and most glasses.

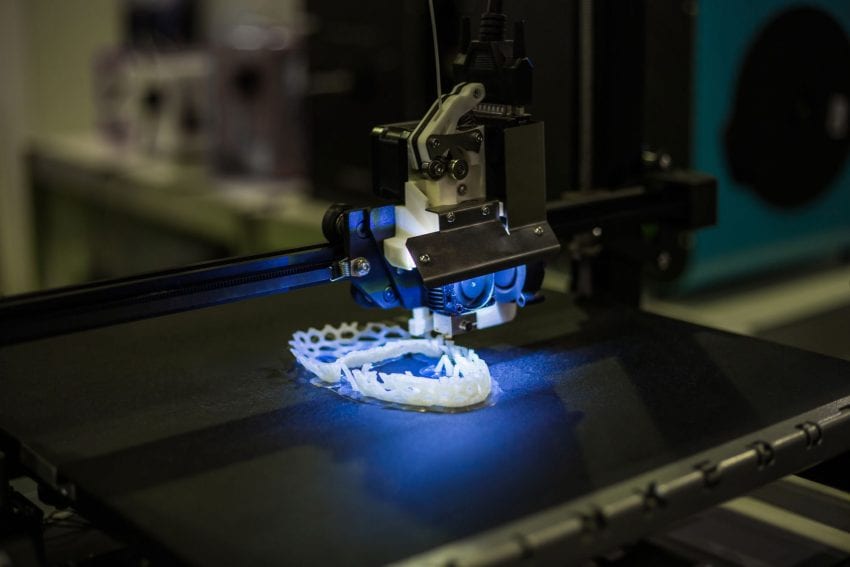

Acrylonitrile Butadiene Styrene (ABS)

ABS is the plastic of choice by many prototype manufacturers around the globe due to its low shrinkage, great forming properties, and comparative cheapness.

Advantages of ABS

- Highly resistant to most of the agents

- High shock-resistance

- Glossy finish

Disadvantages of ABS

- Not very strong as compared to other plastics

- Low working temperature < 90°C

- Slightly Toxic

- High shrinkage rate

Common uses of ABS

ABS is ideal for 3D printing and is the material of choice for almost all custom and DIY printing needs. Being light in weight, ABS is also used in mobile enclosures and is ideal for any plastic prototype if you are on a budget.

Polyoxymethylene (POM)

POM is the only plastic having the closest to a crystalline microstructure as compared to other ones. Due to this, POM exhibits several properties as that of metal.

Advantages of Polyoxymethylene

- High strength

- High fatigue resistance

- Good high-temperature stability

- Rigid

- Corrosion-resistant

Disadvantages of Polyoxymethylene

- Uneven shrinkage

- Hard to predict the pattern while molding

- Hard to cut and shape

Common uses of Polyoxymethylene

POM is used in plastic pumps and used in locations that do not swell during moisture absorption. POM is also used in engineering parts and machines that are exposed to water and need durable plastic parts.

PolyMethylMethAcrylate (PMMA)

Though you might not be familiar with term PMMA, you are familiar with Acrylic glass. They both are names of the same thing. PMMA looks like glass, and it is the material of choice by many prototype manufacturers looking for a glass alternative.

Advantages of PMMA

- Highly transparent

- Shatter-resistant

- Corrosion resistance

- Easy to process

Disadvantages of PMMA

- Brittle as compared to other plastics

- Weak towards the water and some hydrocarbons having alkyne elements

- Swells in water

Common uses of PMMA

PMMA is used in automotive lamps as well as in some traffic lights. Being transparent, PMMA is also used in lenses and medical devices. PMMA is an excellent alternative to glass and used in materials looking to replicate glass aesthetics.

With some of the commonly used plastics shown above, along with their pros and cons and common uses, let’s look into what to see in the plastic prototype manufacturer before making your final choice.

How has China become a leader in the prototyping industry?

Ask anyone around for the best place to get your prototyping needs fulfilled, and the chances are that the majority of them will be quoting China as the best option. Why most of the overseas companies favor the Chinese market, you may ask? Well, the reason is quite self-explanatory. China has worked and made huge progress regarding the technical level, a variety of product quality, and output.

In the year 2017, China had over 400,000 CNC machine tool production units with that number every year. In China, the annual CAGR for plastic prototype manufacturing has been more than 35%. According to several reports, very few countries comes even close to this CAGR. The Chinese government has also played a major role in the success of its manufacturing industry with huge incentives to foreign investors and local manufacturers.

Why selecting the right plastic prototype manufacturer is a necessity?

It is crucial that the designer must select the best plastic parts manufacturer as the prototype is what the whole product will be based on. Here are some of the benefits once your plastic prototype is made from the right manufacturer.

- Faster Delivery

With rapid plastic prototyping, there is no need to set up molds and then clear off the excessive run of plastics and all like in case of plastic injection molding machine. With CNC manufacturing, the prototype is made right off the plastic block via subtracting manufacturing with no wastage of time. Talk about a fast manufacturing technique, and there you have it.

- Better surface finishes

Selling your prototype to a client can be a hard task itself, and it’s even harder if the prototype has some cosmetic defect as a result of poor workmanship. Therefore, it is smart to get your prototypes done by the masters in the field.

- Tighter tolerances

With machining, you can reach to very high tolerances, to levels that are unable to be met with traditional manufacturing techniques. Nowadays, most Chinese prototype manufacturers can produce parts within .001 inches of the specifications given by the client. If your plastic prototype needs to be highly precise and accurate, them getting it machined from the best in the class is highly recommended.