The world of manufacturing has been undergoing a seismic upheaval over the past thirty years. While new markets, manufacturing methods, and technology have opened up exciting new opportunities for companies to reduce overhead and deliver higher quality products, these very same developments have made the industry more competitive than ever before.

For decades, the narrative that dominated industrial news was the narrative of globalization: for many commentators, it seemed self-evident that the future of manufacturing was overseas, in countries with less stringent labour regulations and larger workforces.

But with the rise of automation, this narrative has been drawn into question. As assembly lines become more robotic and less reliant on manual labour, manufacturing in North America has become cost-effective in again.

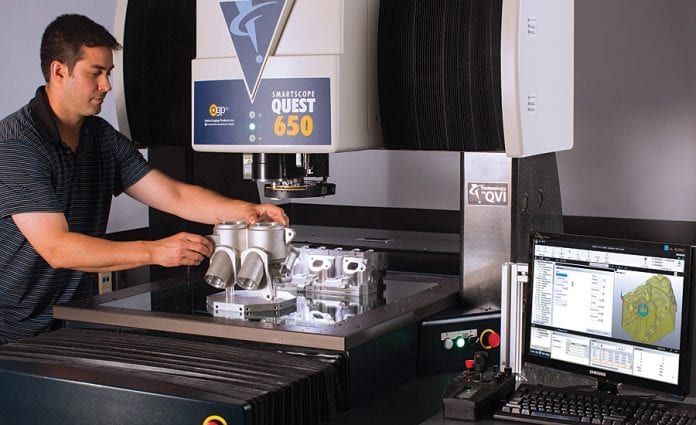

As the domestic industry grows and competition becomes fiercer, it is usually the most New Metrology Tools — the ones that can adapt their manufacturing model to a variety to different needs — that are most successful. This is where coordinate measuring machines (CMMs) equipped with the latest cutting-edge software are making a big difference.

All manufacturers rely on metrology to ensure that the parts and products they are producing match blueprint specifications. Whether that means a factory-floor employee using a set of callipers, or a CMM running the latest software, the principle is the same: you can’t tell whether a part has come out error-free without measuring it.

The latest CMMs use sophisticated tactile probes, laser scanners, and white light measuring machines to provide fine-grained metrology solutions for parts of all sizes. And as those who follow the latest industry news and information about CMM equipment will know, not only is the resulting data far more accurate than manual measuring would be, CMMs can catch extremely small errors that may point toward machine degradation further upstream in the production cycle.

By catching even the smallest errors, and warning of mistakes before they happen, CMMs reduce the amount of time that needs to be spent correcting errors, and makes the whole production line more efficient.

For years, manufacturing industry experts have been heralding the arrival of the fourth industrial revolution, or “Industry 4.0.” Where earlier industrial revolutions brought in greater mechanization and the concept of the assembly line, the latest industrial revolution is predicated on the power of tech.

Using complex wireless networks, smart machines are increasingly becoming discrete functions in a larger collaborative system in which every component communicates with every other component. Not only does this make production lines less reliant on labour markets, it also increases quality while reducing waste.

CMMs equipped with the latest software are playing a vital role in the process. Because they communicate quality control information to other production line components, they are leading the way in creating production lines that can fix their own mistakes with minimal human intervention.

With new manufacturing technologies being perfected and expanded, manufacturing is going through a heady period of expanse. The dream of fully automated production lines is coming closer to being a reality every day. For this reason, manufacturers who want to weather the coming changes should incorporate the latest metrology tools into their own production system as soon as possible.